Invest in automation technologies for liquid-processing equipment to enhance operational efficiency and gain a competitive edge in 2025. The integration of IoT and advanced analytics into these systems allows for real-time monitoring and precise control over processes, resulting in reduced downtime and increased productivity. Consider embracing these technologies as a strategic move to streamline operations and boost profitability.

The projected growth of the liquid-processing equipment market is closely linked to the rising demand in the food, beverage, and pharmaceutical industries. With consumers increasingly prioritizing product quality and safety, manufacturers are compelled to upgrade their equipment. Implementing cutting-edge purification and filtration technologies will meet these quality standards, ensuring compliance and customer satisfaction.

Cost considerations play a significant role in purchasing decisions for liquid-processing equipment. As sustainability becomes a priority, opting for energy-efficient models can significantly reduce operational costs and minimize environmental impact. Conduct thorough research on the energy consumption and lifecycle costs of new equipment before making investment decisions, paving the way for long-term cost savings and sustainability.

Global supply chain disruptions have highlighted the necessity for flexible and adaptive manufacturing processes. Investing in modular liquid-processing systems provides the flexibility needed to adapt to dynamic market demands. Such systems enable manufacturers to scale operations efficiently, ensuring that they can meet both current and future industry requirements without significant downtime or resource allocation adjustments.

Technological Innovations and Trends

Consider integrating smart sensors into your liquid-processing operations to significantly enhance efficiency and precision. These sensors enable real-time monitoring, reducing wastage and minimizing energy consumption. Leverage predictive maintenance tools powered by AI and machine learning to anticipate equipment failures, thus optimizing operational uptime and reducing unplanned downtime.

Adopt advanced automation solutions tailored for your specific industrial needs. Automation not only speeds up processes but also ensures consistent quality, helping you stay ahead in a competitive market. Look into modular equipment designs that allow easy scalability and customization, adapting quickly to changing production requirements.

Embrace developments in sustainable materials and green technologies to meet regulatory requirements and public demand for eco-friendly practices. This might include the use of modular membranes for filtration, which maximize resource efficiency and lower environmental impact. Keep an eye on emerging technologies like digital twin technology, which can provide detailed simulations of your processes, aiding in better decision-making and process optimization.

Advancements in Automation Technologies

Integrate advanced sensors and IoT capabilities to transform your liquid-processing operations, reducing errors and maintaining consistency across tasks. Robotic process automation now allows your systems to handle repetitive and manual operations with precision, freeing human resources for more value-added activities.

By investing in machine learning algorithms, anticipate maintenance needs before failures occur, extending the lifespan of equipment and minimizing downtime. Predictive maintenance uses real-time data and historical trends, ensuring seamless production flow and lowering repair costs.

Consider automating quality control processes. Automated systems can detect anomalies faster and more accurately than manual checks, maintaining high product standards and compliance effortlessly. This–coupled with AI-driven analytics–provides real-time insights into production quality, facilitating instant adjustments.

Energy management in liquid-processing benefits greatly from smart automation systems. These systems optimize energy consumption by adapting to varying loads and operating conditions, leading to substantial cost savings and supporting sustainability goals.

Implement advanced data analytics for informed decision-making. Automate the collection and analysis of vast quantities of data generated during operations, enabling quick identification of inefficiencies and opportunities for process enhancements.

Incorporating these automation technologies not only boosts operational efficiency but positions your business at the forefront of innovation. Investment in automation is no longer a mere option; it’s a strategic move for long-term competitiveness and growth.

Impact of IoT on Liquid-Processing Systems

The integration of IoT technology in liquid-processing systems significantly enhances real-time monitoring capabilities. By utilizing smart sensors, companies gain instant access to data on flow rates, pressures, and temperatures, allowing for optimized operations and preemptive maintenance.

Implement advanced IoT analytics to predict potential system failures before they occur. This proactive approach reduces downtime and decreases maintenance costs by up to 30%, according to industry reports. Moreover, IoT-driven insights enable precise adjustments in processing parameters, thereby improving the quality and consistency of the final product.

Leverage IoT platforms to facilitate seamless communication between equipment components. This interconnectedness ensures more accurate data collection and streamlined process control across the entire liquid-processing lifecycle. Enhanced data sharing leads to better decision-making and faster response times to any anomalies, dramatically improving operational efficiency.

Consider cloud-based IoT solutions for scalable data storage and processing power. This scalability supports the growth needs of liquid-processing facilities without the necessity for extensive on-site investments. Additionally, the cloud infrastructure offers greater flexibility in data analysis, driving more informed business strategies.

Invest in cybersecurity measures to protect sensitive data transmitted across IoT networks. Ensuring robust security protocols not only safeguards information but also builds trust with clients and partners, providing a competitive edge in the market.

Role of AI in Process Optimization

Begin integrating AI-driven analytics to precisely forecast demand and adjust liquid-processing parameters automatically. This reduces waste and improves yield by up to 30%, according to recent industry reports.

Deploy machine learning algorithms to continuously monitor equipment performance. These systems detect anomalies and predict maintenance needs, minimizing downtime and extending machinery lifespan by an average of 20%.

Implement real-time AI optimization tools to adjust production schedules dynamically. This real-time adaptation to supply chain changes enhances responsiveness and maintains optimal production rates, supporting a more agile operation.

Utilize AI-powered quality control systems to assess product characteristics at multiple stages. These systems ensure consistency by performing detailed analyses, thus reducing defects by 15% and improving overall product quality.

Incorporate predictive algorithms for inventory management that dynamically adjust inventory levels. This reduces holding costs and ensures timely material availability, enhancing cash flow and operational efficiency by an estimated 25%.

By embracing these AI solutions, companies can significantly elevate operational performance, achieving more sustainable and efficient liquid-processing operations in the competitive 2025 market landscape.

Economic and Regulatory Factors

Diversify your investment strategy by considering equipment compatible with multiple regulatory standards. This approach not only strengthens your operational resilience but also minimizes potential disruptions.

Stay Ahead of Regulatory Changes: Global regulations are becoming more stringent, particularly regarding environmental impact and energy consumption. Invest in equipment that meets or exceeds these requirements to avoid costly compliance fines and potential operational downtime.

Economic Fluctuations Influence Costs: Anticipate fluctuations in raw material prices and adapt procurement strategies accordingly. Building a robust supply chain network with multiple suppliers can mitigate risks associated with price volatility.

Localized manufacturing may offer not only cost benefits but also alleviate tariff burdens. Evaluate the strategic advantages of near-shoring to reduce logistics costs and improve supply chain efficiency.

Keep abreast of international trade agreements that could affect import/export tariffs. Align your supply contracts to take advantage of favorable terms, thus optimizing your cost structure.

Finally, explore financing options such as government grants or subsidies aimed at promoting green technology. These incentives can significantly reduce initial investment costs for state-of-the-art liquid-processing equipment.

Projected Market Growth and Challenges

Expect significant growth in the global liquid-processing equipment market, projected to reach $101 billion by 2025, driven by increased demand in food and beverage, pharmaceuticals, and water treatment industries. To capitalize on this opportunity, manufacturers must enhance production capabilities and invest in R&D for more energy-efficient equipment.

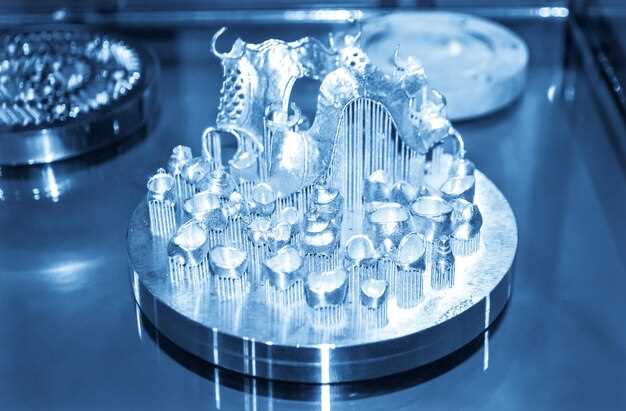

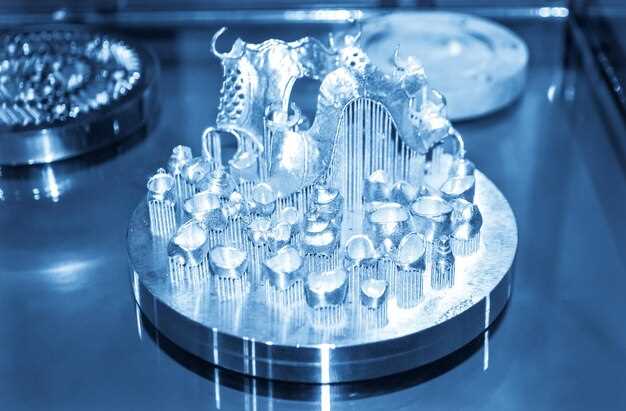

However, businesses must address several key challenges to maintain competitiveness. The rising cost of raw materials such as stainless steel and aluminum impacts equipment affordability. Implementing strategic procurement practices can mitigate some of these cost pressures. Additionally, navigating complex regulatory frameworks requires compliance expertise and advanced monitoring technologies.

Technological advancements, while offering competitive advantages, necessitate substantial capital investment. Emphasizing partnerships with tech innovators can bridge this gap, providing cost-effective access to cutting-edge solutions. Therefore, remaining agile and adaptable in strategy development is imperative for sustained success in this rapidly evolving market.

| Year | Projected Market Size (Billion USD) | Key Drivers |

|---|---|---|

| 2022 | 80 | Food & Beverage Expansion |

| 2023 | 85 | Pharmaceutical Innovation |

| 2024 | 93 | Water Treatment Needs |

| 2025 | 101 | Technological Integration |

Influence of Environmental Regulations

Upgrade your equipment to enhance efficiency and compliance with strict environmental standards. Many regions are tightening controls on liquid-processing outputs, mandating reductions in pollutants and waste. Consider investing in advanced filtration and separation technologies. These systems not only meet emissions targets but also offer cost savings by recycling water and other valuable resources.

Focus on automation to streamline processes and improve accuracy in monitoring chemical usage. Implementing sensors and control systems reduces human error and ensures adherence to legal requirements. As regulations evolve, maintaining flexibility in your installations will allow you to adapt without extensive overhauls.

Engage in collaborative efforts with regulatory bodies and industry groups to stay informed about upcoming changes. Participating in these platforms helps anticipate shifts that could impact operations and costs. By aligning strategies with the sustainable practices being promoted, companies can gain a competitive advantage and enhance their reputation.

Partner with suppliers who provide eco-friendly equipment options and have a proven track record in supporting compliance. This collaboration enables access to innovative solutions that reduce environmental impact while fostering corporate responsibility. By making sustainability a core part of your business strategy, you not only comply with regulations but also contribute positively towards the global effort of environmental preservation.

Investment Opportunities in Emerging Markets

Focus on Southeast Asia for promising opportunities in liquid-processing equipment investments. The region’s growing manufacturing sectors, especially food and beverage, provide demand for advanced processing equipment. As urbanization accelerates, local industries are keen to upgrade facilities, making them prime targets for investment.

- Indonesia: With its large population and expanding middle class, Indonesia presents a lucrative market. Investing in energy-efficient liquid-processing technologies can capture the attention of businesses aiming to reduce operational costs.

- Vietnam: Rapid industrialization combined with favorable government policies has turned Vietnam into a manufacturing hub. Capitalize on local incentives for green technologies to align with Vietnam’s sustainability goals.

- Thailand: Already established as a regional leader in food production, Thailand offers opportunities in modernizing its processing equipment. Leverage Thailand’s push towards Industry 4.0 by introducing smart processing solutions.

The African market, particularly Sub-Saharan Africa, is another area ripe for exploration. Progress in infrastructure development and economic policies make the region attractive for investments:

- Nigeria: As Africa’s largest economy, Nigeria is committed to boosting its local manufacturing sector. Consider partnerships with local firms to facilitate the introduction of innovative liquid-processing technologies.

- Kenya: With a growing focus on agro-processing, opportunities abound by offering equipment that enhances production capabilities while being energy-efficient.

Identifying regional demand shifts and aligning investment strategies with local industrial trends will enable investors to maximize returns in these emerging markets. Prioritize partnerships with local entities to navigate regulatory landscapes and cultural nuances effectively.

Supply Chain Considerations in a Post-COVID World

Bolster your supply chain resilience by decentralizing production and sourcing strategies. Companies should diversify their supplier base, utilizing regional partners to mitigate risks associated with global disruptions. Consider the adoption of digital supply chain technologies such as AI-driven demand forecasting and inventory management tools, which enhance visibility and adaptability. Implement flexible contracts that offer dynamic response capabilities to fluctuating market conditions, ensuring continuity even amidst unforeseen challenges.

Invest in robust communication frameworks that allow for real-time data exchange between stakeholders, facilitating proactive decision-making and quick adaptation to changes in supply and demand dynamics. Boost warehouse automation to reduce dependency on manual labor and improve efficiency in processing and distribution of liquid-processing equipment. Leverage blockchain technology for enhanced transparency and traceability, fostering trust and compliance throughout the supply chain.

Prioritize risk assessment and management by regularly evaluating potential vulnerabilities within the supply chain. Engage in scenario planning exercises to prepare for various supply chain disruptions, allowing businesses to pivot swiftly as new challenges arise. Additionally, implement sustainable sourcing initiatives to meet increasing consumer demand for environmental responsibility and compliance with evolving regulatory standards.

Q&A:

What are the key trends expected to influence the liquid-processing equipment market in 2025?

The market is anticipated to be shaped by several factors, including advancements in automation and digital integration. Automation is becoming increasingly essential for optimizing production efficiency and reducing manual errors. Additionally, environmental sustainability will play a significant role, with companies focusing on energy-efficient and eco-friendly equipment. Lastly, the rising demand for precision and customization in processing solutions due to diverse consumer preferences will drive innovation in the sector.

How are manufacturers responding to the growing demand for more sustainable liquid-processing equipment?

Manufacturers are investing heavily in research and development to create equipment that uses less energy and incorporates recyclable materials. Many are implementing closed-loop systems that minimize waste generation and enable the reuse of resources. Partnerships with technology firms are also on the rise, with the goal of integrating smart systems that monitor and optimize energy use in real-time, further supporting sustainability goals.

What challenges might affect the growth of liquid-processing equipment in 2025?

A range of challenges could impact the market growth. Supply chain disruptions, particularly regarding the sourcing of essential materials, pose a significant risk. Furthermore, implementing new technologies requires skilled personnel, and the current shortage of qualified technicians could slow down technological adoption. Regulatory changes focusing on environmental standards may also lead to increased compliance costs for manufacturers.

How is the integration of IoT technologies expected to transform the liquid-processing equipment market?

IoT integration is expected to significantly enhance equipment operations by offering real-time monitoring, diagnostics, and maintenance through advanced sensors and connectivity. This transformation enables manufacturers to maximize uptime and operational efficiency while reducing costs. Predictive maintenance, powered by IoT, also helps in preemptively addressing equipment issues before they lead to failures, thereby ensuring more consistent production processes.

In what ways could geopolitical factors impact the liquid-processing equipment market in 2025?

Geopolitical factors such as trade policies and international relations can heavily impact the market. Tariffs and export restrictions may influence the cost and availability of raw materials and finished goods, while shifts in international relations might affect global supply chains and distribution networks. Companies may need to adopt flexible strategies and diversify their supply sources to mitigate these risks.

How is the demand for liquid-processing equipment expected to change by 2025?

By 2025, the demand for liquid-processing equipment is anticipated to rise. This growth can be attributed to several factors, including the expansion of industries such as food and beverage, pharmaceuticals, and chemical processing, which rely heavily on these systems. Additionally, increased emphasis on sustainability and energy efficiency is driving companies to upgrade their equipment to meet new standards and reduce operational costs. The integration of advanced technologies, like automation and IoT, is also enhancing the efficiency and capabilities of these machines, further fueling market demand.

What technological advancements are influencing the development of liquid-processing equipment?

Several technological advancements are reshaping the development of liquid-processing equipment. Automation and IoT have become integral, allowing for real-time monitoring and control, which improves efficiency and reduces downtime. The implementation of AI and machine learning is also playing a significant role, enabling predictive maintenance and optimizing process parameters. Furthermore, advancements in materials science have led to the creation of more durable and corrosion-resistant components that extend the lifespan of equipment. These innovations are crucial for manufacturers looking to stay competitive in a rapidly evolving market.